BFL Stainless Steel CNC Cutting Tools DNMG150408-MA

Product Description

Feature

High stability, high abrasive resistance and high resistance of plastic deformation

Advantages

1. Made in 100% virgin carbide powder, excellent wear resistance and toughness;

2. High performance CVD/PVD coating, with super hard and smooth surface;

3. Performed 200% inspection, under ISO9001:2015 quality system control;

4. Professional chip-breaker design, provides perfect cutting performance;

5. Precise dimension, high accuracy;

6. Super long and consistent tool life;

Specification

Coating Grades Properties Overview

Grade | ISO Classification | Color | Recommend for Application |

BPGO5B | M05-M15 | Cyan-blue gray dark | With high hot hardness and good resistanceto plastic deformation. Suitable for high speed cutting and finishing process of austenitic stainless steel.quenched and carbon steel. |

BPG20B | M10-M30 | Cyan-blue gray dark | PVD coated micro-grain carbide.Use for a varity of stainless steel finishing at medium to low cutting speed.When need excellent edge strenght and high surface quality.provide the perfect ride cutting.A high thermal shock resisitance.Suitable for light interrupted cuts . |

BPG308 | M25-M40 | Purple Yellow | PVD coated carbide.For austenitic stainless steel and duplex stainless steel semi-finishing to rough at low to medium cutting speed.High thermal shock resistance. Ideal for quickly interrupted cutting. |

Product Show

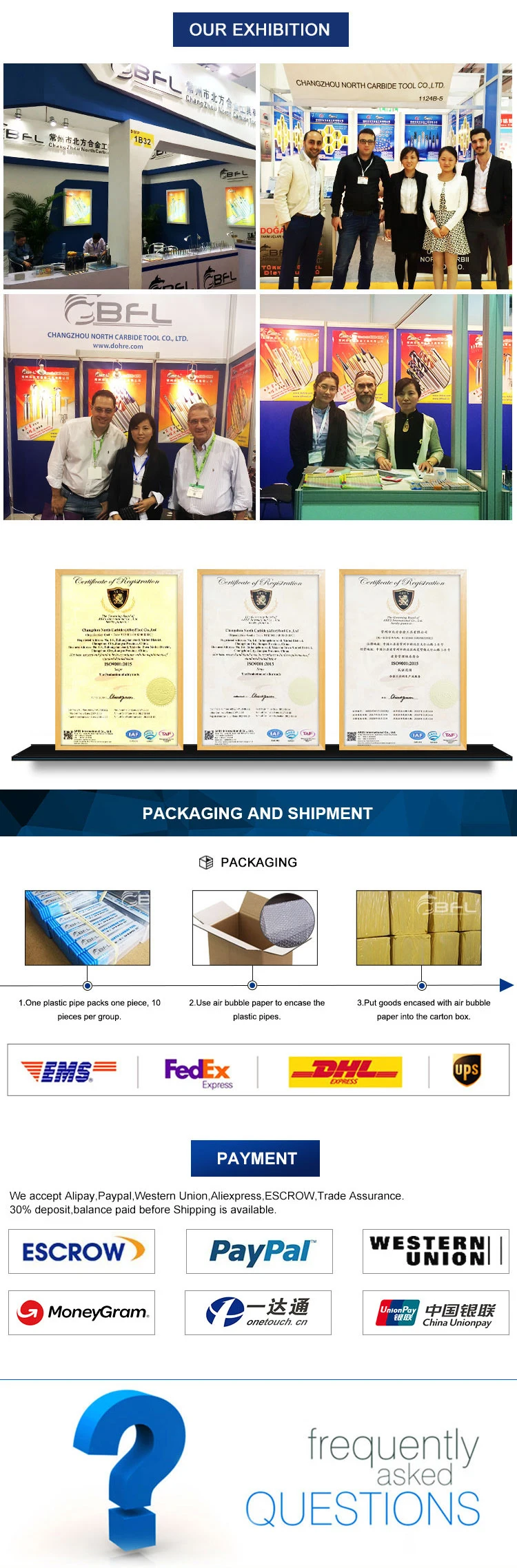

Company Information

Changzhou North Carbide Tool Co., Ltd is a high-tech enterprise which specializes in the manufacturing and processing of tools and mechanical components and parts. For over a decade, the Company has been embracing itself with a philosophy of “Customer Foremost” and the entrepreneurship of sincerity, honesty, pioneering and forging ahead. The Company aims to win the trust and praise of a large majority of customers as well as a vast market by virtue of its sophisticated technologies, premium qualities, reasonable prices, complete categories and exquisite packages, first-class services.

The Company has powerful technological strength, together with massive imported high-precision manufacturing, inspection and testing equipment. The Company gives priority to introduction of the advanced manufacturing and monitoring machines home and abroad, including but not limited to CNC cutter grinding machine tools from RPL-LOMTIC in Switzerland and WALTER in Germany, as well as cutter checking and inspection instruments from EOUER in Germany, all tremendously enhances the manufacturing capacity of the company, quality of products and competitiveness in market expansion.

The scope of manufacture of the Company extends from carbide drill bits, milling cutters, reamers, plug gauges, alloy cutters, carbide saws with coarse teeth, helical end mills, brazed shank tools, indexable tools, machining center tools, to tool handles, etc, with comprehensive applications in the mechanical processing, of automobiles, moulds, and plastics, and dedications to the provision of premium cutters for modern industries. The Company is fully recognized by massive customers with its proven qualities and excellent services.

FAQ

1. Are you manufacturer? Do you have factory?

We are professional manufacturer,have more than 15 years experience in this field.

2. Is free shipping possible?

We don't offer free shipping service,but we will give you some discount if you buy large quantity products. And we have cooperation Express Companies,can offer you the best price of shipping cost.

3. Can you send products to our Forwarder in China?

Yes,if you have Forwarder in China,we will glad to send products to him/her.

4.Can you produce Special carbide Tools ?

Yes We can. From 2013 year. Our factory main market change from standard end mills to special tools. Special tools according to your drawing and sample.